Batt Insulation

At May Energy Solutions, we specialize in providing professional residential batt insulation tailored to the unique needs of Texas homeowners. These solutions are designed to significantly enhance your home’s comfort by keeping it cool in the intense summer heat and warm during the cold winter. It’s a budget-friendly option that provides sound absorption, reduces energy expenses, and comes in a range of materials and thicknesses to ensure maximum energy efficiency. Thus, leading to consistent indoor temperature and lower energy bills year-round. Trust us to get the best service of batt insulation in Texas!

Before we connect, let’s discuss the batt insulation process in detail!!

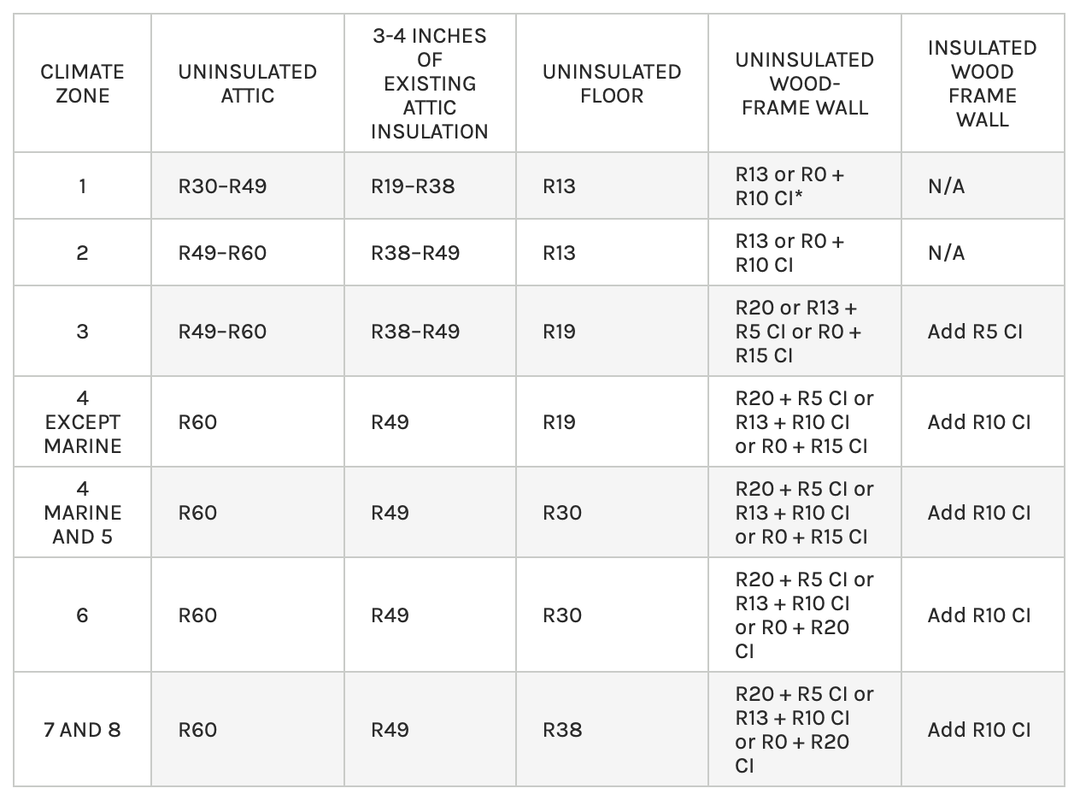

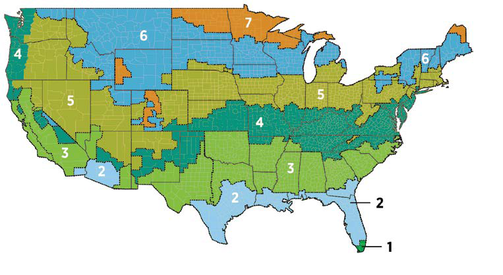

*Note: In the table at right , CI stands for “continuous insulation” that is applied to the exterior of the wall assembly just inside the cladding. Map and chart: www.energy.gov/energysaver/insulation

Our Process of Batt Insulation

Measuring and Cutting the Batt Insulation

We begin by accurately measuring the areas requiring insulation. Using a tape measure, we assess the length and width of the space to ensure precise cuts. Our team then cuts the batt insulation to fit snugly in the stud cavity, leaving a little extra material for a secure fit.

Fitting and Securing the Insulation

Once the insulation is cut to size, our experts carefully place the batt insulation between the wall studs or ceiling or floot joists. We start at the bottom and work our way up, ensuring the insulation is properly positioned without being compressed. The goal is to fill the entire space evenly for consistent thermal performance.

Insulating Corners and Tight Spaces

Corners and tight spaces often require additional attention. Our technicians custom-cut smaller pieces of insulation to fit these areas, ensuring a seamless and effective barrier against heat loss. Special care is taken to tuck the insulation for a snug fit, even in hard-to-reach spots.

Working Around Obstacles

Batt insulation installation also involves accommodating electrical wires, pipes, and other obstacles. We skillfully cut slits or holes in the insulation to fit snugly around these penetrations, ensuring a secure fit without compressing the material.

Why Choose Batt Insulation for Your Property?

Let’s have a look at why Batt insulation is a beneficial investment for your property:

Moisture Resistance

Certain types of batt insulation, such as those made with fiberglass and rock wool, resist moisture absorption. This feature helps minimize the potential for mold growth and structural damage, particularly in humid environments.

Precision-Cut to Fit Any Space

Batt insulation is pre-cut to specific sizes, allowing it to fit perfectly between studs, joists, and beams. By ensuring no gaps or spaces, thermal bridging or air leaks are minimized, and its effectiveness is increased.

Soundproofing Benefits

Its dense, fibrous structure reduces noise transmission between rooms and from outside sources. By absorbing and dampening sound waves, batt insulation minimizes airborne noise, enhances privacy, and reduces echo.

Easy Installation

Batt insulation is straightforward to install, making it quick and hassle-free for professional installers. As a result, labor costs are reduced, and daily disruption is minimized.

Immediate Availability

Unlike some other insulation types, which may require special ordering or long wait times, batt insulation is widely available in various thicknesses and materials. It is a good choice for quick projects or urgent insulation needs.

Consistent Performance in a Variety of Temperatures

Batt insulation ensures reliable performance year after year because its insulation properties remain stable over a wide temperature range.

So, hurry up! Contact our experts and experience the perks of quality batt insulation in Texas service. For queries, call us at (830) 358-7112 or email us at may@mayenergysolutions.com.

FAQs

What materials are typically used for batt insulation?

Batt insulation is most commonly made from fiberglass, consisting of woven fine glass strands. Other materials used for batt insulation include mineral wool (also known as rock wool).

Can batt insulation help with soundproofing my home?

Indeed! Batt insulation can help with soundproofing. Fiberglass and mineral wool batt insulation in particular, are effective at reducing noise transmission due to their dense, fibrous structure.

How does batt insulation's installation process differ from other insulation types?

The installation process for batt insulation involves cutting the rolls or batts to the proper lengths that fit snugly into the cavities between studs, joists, and rafters of walls, ceilings, and floors. This process is relatively straightforward and requires less specialized equipment than other insulation types.

How does batt insulation handle moisture and mold prevention?

Batt insulation, especially fiberglass and rock wool, does not readily absorb water. This property minimizes the potential for mold and mildew growth.